Product Number:RT-18

Customized:Yes

MOQ:1 Ton(s)

Shipment Terms:By Sea,By Train

Price terms:EXW, FOB, CFR are optional

Payment Terms:L/C, T/T, Western Union, PayPal , Cash, Money Gram, Bank Account

Production Time:stock items can be shipped immediately after receipt of payment. Non-stock items normally need 10-15 days to produce, the final delivery time need to be checked before order.

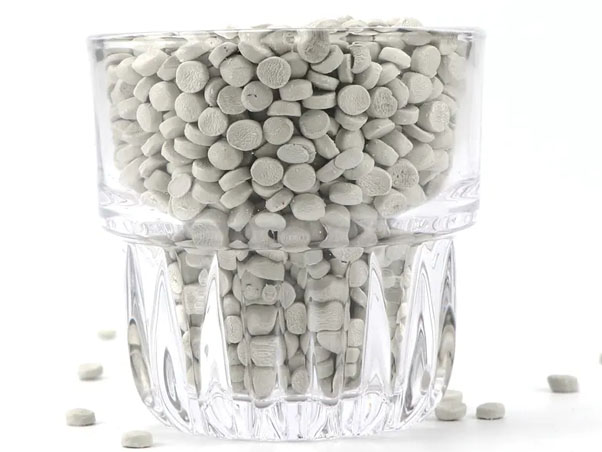

Polypropylene Desiccant Masterbatch

Low Price & High Quality

OEM/ODM

Desiccant masterbatch is a type of plastic additive that is used to prevent moisture-related defects in plastic products. It is made by combining a desiccant, such as calcium oxide or silica gel, with a carrier resin, such as polyethylene or polypropylene, in a pellet form. When added to plastic resins, desiccant masterbatch can absorb any moisture present in the plastic material and prevent it from causing issues like porosity, surface defects, or degradation.

Desiccant masterbatch has a wide range of applications in various industries, including food packaging, electronics, and medical devices. It is especially useful in environments with high humidity, where plastic products are more susceptible to moisture-related damage. China is a leading producer of desiccant masterbatch, with a significant advantage in terms of production capacity and cost-effectiveness.

The production of desiccant masterbatch in China is supported by a well-developed plastic industry and a vast network of suppliers for raw materials. Additionally, Chinese manufacturers have made significant investments in technology and equipment, enabling them to produce high-quality desiccant masterbatch at a competitive price point. With the increasing demand for high-quality plastic products globally, the Chinese desiccant masterbatch industry is expected to continue to grow and expand.

-

Plastic Dana PP Masterbatch Color Red Orange Support Customize Color Masterbatch

Plastic Dana PP Masterbatch Color Red Orange Support Customize Color Masterbatch -

Bulk Supply PP Polypropylene Granules Raw Desiccant Masterbatch For Recycled Plastic Pellets

Bulk Supply PP Polypropylene Granules Raw Desiccant Masterbatch For Recycled Plastic Pellets -

PE/PP Raw Materials 80% Na2SO4 Sodium Sulphate Transparent Filler Masterbatch With High Transparency

PE/PP Raw Materials 80% Na2SO4 Sodium Sulphate Transparent Filler Masterbatch With High Transparency -

Industrial Grade 52% Pigment Black Pellets Masterbatch For Injection Moulding Plastic Pumping

Industrial Grade 52% Pigment Black Pellets Masterbatch For Injection Moulding Plastic Pumping